May/June 2020

Communities: Education

Engineering Education in the Time of Covid

Like every segment of society, engineering education has undergone profound change during the Covid-19 pandemic. Shuttered campuses have turned learning virtual, with engineering faculty forced to adopt new technology for teaching and to figure out how to turn what is often a hands-on education into a remote practice.

Institution-wide, students are dealing with loss of on-campus jobs and housing, and increased need for financial aid. Universities are taking budget hits from refunding student payments for housing and dining and expecting drops in future enrollment, as a recent AP article explained.

NADIR YILMAZ,

NADIR YILMAZ,P.E., F.NSPE

NSPE member faculty are among those adapting to the new reality. For Nadir Yilmaz, P.E., F.NSPE, that’s meant an exponential increase in work. According to the professor and chair of the mechanical engineering department at Howard University in Washington, D.C., spring “break” was spent preparing for the transition to online learning. Since then, what was previously several in-person meetings a week has turned into five or more online ones, plus virtual student office hours.

In addition, Yilmaz points out, he and other faculty “are having to accomplish…online teaching, preparation, and advising around dealing with the education of young children.” The department chair has prioritized keeping school operations functioning as close to normal as possible while pushing aside his own research and professional development.

Students at Howard are receiving “pass/fail” grades for the spring unless they specifically opt for letter grades, Yilmaz explains, although he is concerned this may affect graduate school admissions. Courses that require in-person interaction may be offered over the summer.

Although challenges abound, Yilmaz sees potential for creative strategies developed during a time of turmoil that can later improve online and distance learning overall. He points to faculty’s “solemn promise and utmost responsibility to shape the lives of our students even during these unprecedented times.”

At Ohio University’s Russ College of Engineering and Technology, Dean Emeritus Dennis Irwin, P.E., F.NSPE, says most laboratory research has been put on hold, although exceptions were being granted on a case-by-case basis.

DENNIS IRWIN AS HE APPEARS IN THE MICROSOFT TEAMS ENVIRONMENT

DENNIS IRWIN AS HE APPEARS IN THE MICROSOFT TEAMS ENVIRONMENTThe professor emeritus of electrical engineering has been adjusting to virtually teaching his digital signals and systems class, with its heavy use of mathematical symbology. “My students have been very receptive to my using scanned handwritten notes and using the screen sharing capability of Microsoft Teams to go over them in real time,” he says. In addition, a virtual desktop environment gives faculty and students access to necessary software, such as MATLAB.

Irwin notes he went from “zero experience with online instruction and very rusty lecturing and software skills to a pretty interactive environment in just a few days.” The students and professor helped each other through the “surprisingly few software glitches.”

Based on advice shared in online groups, the PE is focusing on content delivery over homework requirements. Students are navigating challenges such as internet access and family issues, he explains. So, he’s suspended homework assignments and planned a project-based final exam.

On a personal level, Irwin says he’s been doing a lot of household projects. While he’s normally a voracious reader, he hasn’t had much enthusiasm for it. “Somehow reading reminds me of the aspects of life that I am missing,” he says.

ROBERT GREEN’S DESK AT HOME FEATURES AN INSPIRATIONAL STATUE OF HIS HERO, FLEET ADMIRAL CHESTER NIMITZ.

ROBERT GREEN’S DESK AT HOME FEATURES AN INSPIRATIONAL STATUE OF HIS HERO, FLEET ADMIRAL CHESTER NIMITZ.At Mississippi State University’s college of engineering, Assistant Dean Robert Green, P.E., F.NSPE, says despite understandable anxiety about the pandemic and moving to a new learning environment, faculty and staff seem to be coping well and communications have been positive.

The college has a “fairly robust” distance learning program at the graduate level, says Green, including distance classrooms equipped with special recording software. Those tools are now available to all engineering faculty to record lectures for the remainder of the semester.

Green, an NSPE past president, has been impressed by the both the resiliency and work ethic of everyone in the college. Faculty, staff, and students have all pulled together to make changes quickly, finding efficiencies in processes and new ways of working. Complaints have been minimal, he says, and everyone has been willing to pitch in. “It is strange how we feel closer than ever,” he says, “while being physically further apart than ever before.”

But one challenge has been internet access for students, particularly in the state’s more rural areas where high-speed internet is not available. With libraries and extension service offices closed, students are left with the option of accessing wireless networks from parking lots. “I feel for the student who has to take an exam in their car in a parking lot,” Green says.

One lesson we can learn from this pandemic, he adds, is that “as a nation we are woefully ill-equipped with universal internet access. I think we are realizing that it is quickly, if not already, becoming as critical a service as electricity and water.”

INDUSTRIAL ENGINEERING GRADUATE STUDENT EBENEZER OKPIRI CALLS COVID-19 “SERIOUS TRAUMA” FOR STUDENTS

INDUSTRIAL ENGINEERING GRADUATE STUDENT EBENEZER OKPIRI CALLS COVID-19 “SERIOUS TRAUMA” FOR STUDENTSNSPE student member Ebenezer Okpiri, a graduate student in industrial engineering at Northern Illinois University, points to additional challenges he and his counterparts are facing. First came the loss of his job in the campus dining hall. He commends the university’s decision to pay student workers for the remainder of the school year, but later his pending internship interviews were canceled due to the economic downturn. The situation becomes even more dire for students’ families, he adds, when other family members are laid off from their jobs.

Okpiri sees the pandemic’s toll on his friends, too. Some, as they neared graduation, were designing and building devices such as automation systems. Now their work takes the form of software simulations. They tell him they’re “doing everything we can do just to pass, not to understand.”

Covid-19 came unexpectedly, Okpiri adds. Calling it “serious trauma,” he says, “we were not psychologically prepared.” He misses the classroom and is trying to stay motivated and use his time management skills. He has to maintain a 3.0 GPA to stay in the graduate program.

As Green puts it, “these are interesting times, and we will all be different when we exit on the other side.” He sees potential impact on the future of engineering education. “We have all been moved out of our comfort zones,” he says, “and that is where true learning and change occurs.”

While he’s working from home, Green can look to the left on his desk and see a statue of his hero, Fleet Admiral Chester Nimitz. “I can look at it and be reminded that we have been through tough times before and handled them well through good leadership,” says the Navy Reserve Captain. When he looks to the right, he sees a picture of his granddaughter, reminding him of the future. “What we are doing now is what connects the past to the future,” he says.

Engineering Solutions

Around the country, engineering schools and departments are stepping up to help with the global pandemic. From donating their own personal protective equipment to 3D printing masks and face shields to modeling the pandemic and more, engineers are doing what they’re best at—solving problems and protecting the public.

At Mississippi State University, Robert Green explains, the Department of Aerospace Engineering donated more than 1,000 N95 respirator masks to the student health center and local hospital. The masks are typically used in labs and research spaces while cutting or sanding wood or carbon fiber composites.

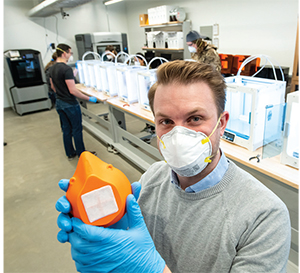

TYLER KERR, UNIVERSITY OF WYOMING MAKERSPACE COORDINATOR, HOLDS UP ONE OF THE FIRST SURGICAL MASKS HE AND HIS TEAM CREATED ON THE STUDENT INNOVATION CENTER’S 3D PRINTERS. CREDIT: UNIVERSITY OF WYOMING

TYLER KERR, UNIVERSITY OF WYOMING MAKERSPACE COORDINATOR, HOLDS UP ONE OF THE FIRST SURGICAL MASKS HE AND HIS TEAM CREATED ON THE STUDENT INNOVATION CENTER’S 3D PRINTERS. CREDIT: UNIVERSITY OF WYOMINGIn addition, researchers in the Department of Electrical and Computer Engineering’s high voltage lab partnered with a local equipment manufacturing company. Together, they’re converting ventilators that operate on battery power for transporting patients to operate on AC power for longer-term use at the University of Mississippi Medical Center. “They were able to quickly design and manufacture a circuit board that will allow the ventilators to be able to switch between AC and DC power,” Green says. As of early April, the lab and Louisville-based Taylor Machine Works had converted 550 ventilators.

When the crisis began, the University of Wyoming’s College of Engineering and Applied Science immediately offered its help to hospitals and clinics around the state, explains Cameron Wright, P.E., interim dean and professor of electrical and computer engineering. In addition to donating lab and personal protective equipment, the NSPE member says, “our 3D printers have been working overtime to fabricate various items that were requested.” The makerspace coordinator in the Student Innovation Center, Tyler Kerr, and his team prototyped designs and then began producing surgical masks via 3D printers and laser cutters. They are being donated to Cheyenne Regional Medical Center, whose staff reached out to Kerr for assistance.

THE UNIVERSITY OF KENTUCKY’S JAMES B. BEAM INSTITUTE IS PRODUCING HAND SANITIZER FOR HEALTHCARE WORKERS AND FIRST RESPONDERS. CREDIT: UNIVERSITY OF KENTUCKY PHOTO/ MARK CORNELISON

THE UNIVERSITY OF KENTUCKY’S JAMES B. BEAM INSTITUTE IS PRODUCING HAND SANITIZER FOR HEALTHCARE WORKERS AND FIRST RESPONDERS. CREDIT: UNIVERSITY OF KENTUCKY PHOTO/ MARK CORNELISONThe engineering college has also helped create the statewide Wyoming Technology Coronavirus Coalition, to “coordinate high-impact technological efforts to assist the state.”

Johns Hopkins University’s Center for Systems Science and Engineering is tracking Covid-19’s spread in real-time on an interactive dashboard. Data is available to download from the center, a research collective within the Baltimore university’s Department of Civil and Systems Engineering. CSSE is also modeling the spread of the virus across the world.

And the University of Kentucky’s multidisciplinary James B. Beam Institute for Kentucky Spirits has begun making hand sanitizer and also developed an instructional video for other distillers. Chemical engineering professor Bradley Berron oversaw the FDA-approved formulation, which uses high-proof ethanol and glycerin.